High-precision positioning system: ±0.025mm repeatable positioning accuracy

Intelligent: intelligent error/duplicate code prevention

Imported laser, high stability, long life

Configurable optical fiber, carbon dioxide, ultraviolet, green light, multiple wavelengths, suitable for various applications

Based on a unified platform structure, a variety of lasers are available, and replacement is flexible and fast

CCD industrial camera realizes positioning, and can be equipped with simultaneous printing and reading

High-speed X-Y axis motion module, carrying laser marking system, and mobile marking

Track supports automatic width adjustment, and automatic flipping mechanism is optional

High-rigidity integrated manufacturing frame

The panel separation function and parameters for end mills/fixtures are easy to set.

Processing efficiency and end mill usage data are clearly displayed.

The historical message pane makes it easy to query operation records.

It features router bit life management, maintenance alerts, and spindle speed settings management.

Equipped with high-speed CCD vision automatic calibration system.

Can simulate cutting paths to assist in program programming, ensuring cutting path accuracy.

Combined with full-board scanning and offline programming functions, it enhances path editing efficiency.

Maintenance time can be set.

Time to clean the dust filter bag.

The system will remind operators to perform maintenance on the equipment regularly.

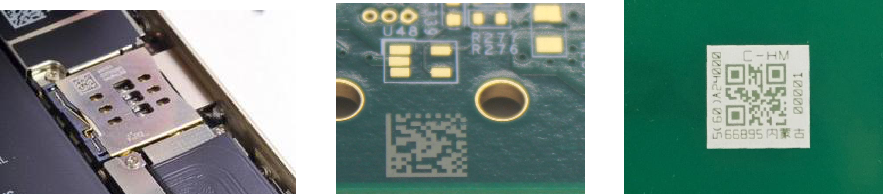

The barcode camera can dynamically capture and recognize QR codes from any position in real-time applications.

By adding a barcode reader, the barcode on the PCBA can be recorded to the computer, or the MES system can receive server messages to identify the NG board's barcode and perform classification processing.

The PCB depaneling machine uses an integrated welded design structure, ensuring stability and high strength.

It is made of cast aluminum with a one-piece molding process, offering excellent oxidation resistance, no deformation, no displacement, long service life, and guaranteed precision.

Optional Central Control System: Unified management and real-time monitoring via network IP.

Remote Device Unified Management: Remote monitoring via mobile app.

It can be used with different types of laser heads to mark one-dimensional codes, two-dimensional codes, text and other information on CM card slots, PCB white oil boards, and PCB green oil boards, and can be read and verified after marking.

Fully automated, through the standard SMEMA interface, it can be connected to the SMT production line for online operation, and can also be used with automatic loading and unloading machines to form an offline workstation, which can have its own internal flip mechanism.