Improve the efficiency of board separation

Eliminate scrapped boards

No dust, low stress

Suitable for cutting high-component PCB boards of various complex shapes, flexible and efficient

Applicable to automotive electronics, medical, military and other fields;

Solve the problem of rapid line change and production conversion, and save the cost of tooling and fixture production.

Visual automatic recognition of cutting path;

Visual appearance inspection function after cutting;

Discharging can be connected to automated testing, Robot and other workstations;

Transplanting axis can rotate 0-180° to achieve mirroring, fork plate, OK, NG product screening and tray stacking functions.

High-speed dual-spindle panel splitting doubles production capacity

Suitable for cutting large PCB boards:

GAM330: 300*350mm

GAM330L: 450*500mm

GAM330X: 470*650mm

Small footprint

CCD vision automatic alignment system

Double-table cutting, cutting range 300*350mm

Small splitting stress, high precision, suitable for PCBA boards of any shape

Double-layer track, carrier reflow, and full-line automated production

Small footprint, more flexible placement.

High-power laser, sustainable processing.

Combination of precision and stability

Granite machine, cross-shaped structure.

X/Y axis is more stable, compact and easy to use.

Imported scanning galvanometer, control card and telecentric lens.

No high-voltage power supply, convenient, safe and easy to use.

Clean processing

Multi-function, automated

Dual platform, high speed, high precision

Easy and fast operation

Three-section track online, specially designed for SMT production line

No contact, no stress, low dust, fast and flexible, high production capacity

Laser stress-free board splitting,

Can cut PCBA/FPCA of any shape,

Micron-level high-precision cutting, automatic positioning, focusing, etc.;

The suction system can completely eliminate cutting exhaust gas, eliminating hazards and environmental pollution.

Ultra-high board separation efficiency

High precision, dust-free

Supports fast line change

Can be connected to front-end and back-end automation lines

It can cut V-groove connected PCB boards, LED aluminum substrates and copper substrates.

It can cut circuit boards with V-groove edge component distance greater than 0.2mm.

It uses cylinder pulling method for cutting, counting, automatic stop function, and safety.

The operator can operate safely and foolproof cutting to ensure that the operator cannot cut the PCB board badly.

The cutter probe uses the plane of the incision, and the board stress is less than 400 microstrain, which will not cause component damage.

The blade replacement cylinder is simple and convenient, which can solve the problem of bad board cutting caused by manual and knife-feeding board cutting machine.

Simple small PCB splitter, high production efficiency, 1 second cutting

Can cut unlimited length PCB boards

Fast speed and high production capacity

High efficiency, 6 to 8 panels can be divided into one minute

One-piece casting

Stable and durable

No dust or residue

Unlimited length of split boards

Ordinary PCB depaneling machines for light strips can only cut a small piece at a time, so the entire board of light strips needs to be cut multiple times, which has low production efficiency.

Multi-blade and multi-group PCB depaneling machines can complete the cutting of the entire panel at one time, with ultra-high depaneling capacity.

High-precision positioning system: ±0.025mm repeatable positioning accuracy

Intelligent: intelligent error/duplicate code prevention

Imported laser, high stability, long life

Configurable optical fiber, carbon dioxide, ultraviolet, green light, multiple wavelengths, suitable for various applications

One-touch operation, the entire cleaning process is fully automatic, and the rinse liquid is automatically added and discharged without manual intervention.

The equipment has low energy consumption, low operating noise, no pollution, energy saving and environmental protection, overall stainless steel structure, and small footprint.

High efficiency

Cost saving

Environmentally friendly and pollution-free

Quality guaranteed

Prevent PCB warping, cracking and solder joint failure caused by stress

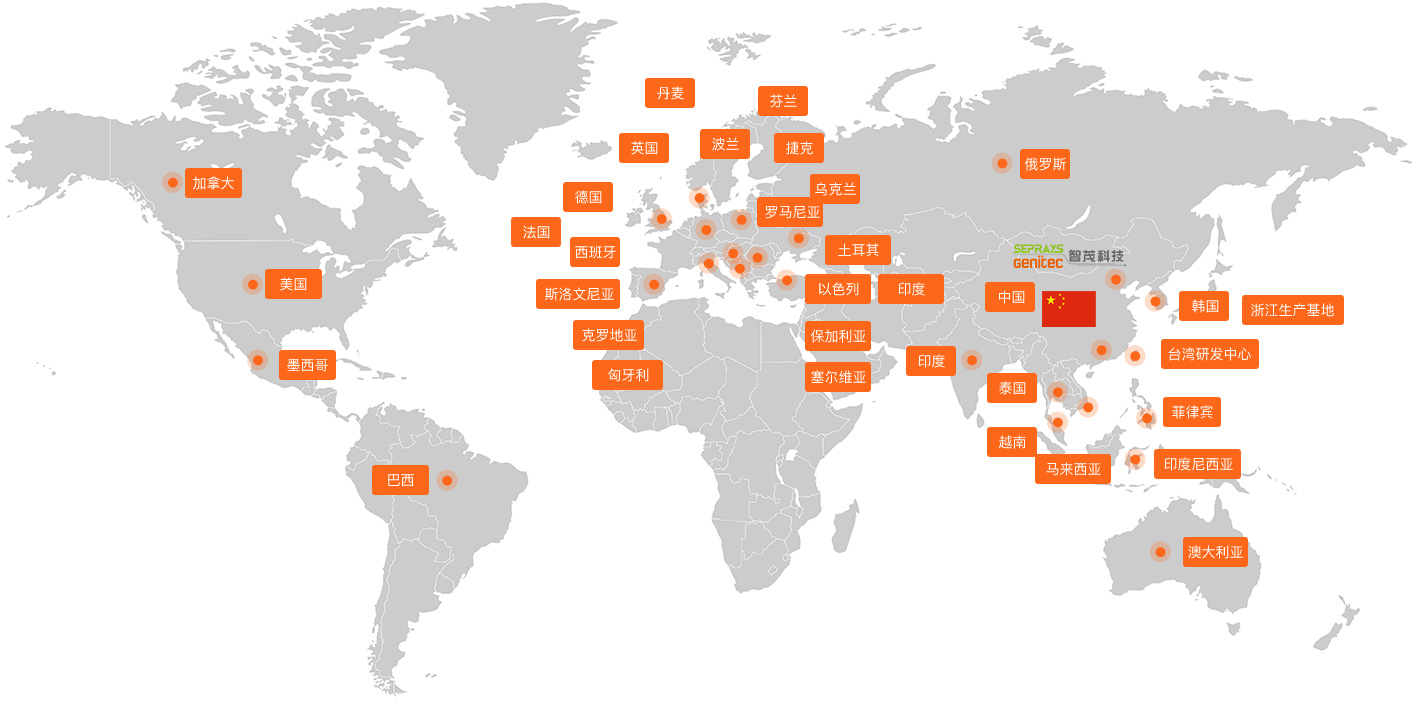

Genitec was founded in Taiwan in 1993 as a research and development center. In 2002, it established a branch in Dongguan, which became a subsidiary in 2013, handling global sales and technical training. In 2003, a 20,000㎡ industrial plant for equipment production was built on land purchased in Zhejiang. A subsidiary was established in Suzhou in 2020.

For over 30 years, Genitec has focused on PCB/FPC depaneling, specializing in Router, laser, V-groove, and punching depaneling machines, as well as automated loading/unloading and palletizing solutions. It is a high-tech enterprise integrating R&D, production, sales, and service.

Fully Automated: Reduces labor and increases efficiency.

High Quality: Precision assembly production with self-inspection functionality.

Digitalization: Self-developed software system that collects data and tracks the entire process

Loading Machine → Laser Etching Machine → Printing Machine → SPI Testing Machine → Pick-and-Place Machine 2 → AOI Testing Machine → Reflow Soldering → AOI Testing Machine → Zhimao Online PCB Separator → Zhimao Sorting and Stacking Machine → AGV Cart

Streamlined process

High output

Labor cost savings

From April 22 to 24, 2025, NEPCON will host a world-class industrial technology event, focusing on the latest technologies and innovative applications, injecting new impetus into the development of the industry. As a leading company in the field of depaneling machine manufacturing, Zhimao will present a number of innovative products to show global customers our cutting-edge technology and profound accumulation in the field of depaneling machines.

2025-04-25.NEPCON ASIA 2024 was successfully concluded at the Shenzhen International Convention and Exhibition Center from November 6 to 8, 2024. This exhibition not only brought together top electronic production equipment manufacturers from all over the world, but also became an important platform for displaying the latest technologies and promoting industry exchanges. As one of the important exhibitors of this exhibition, the Zhimao brand shined during the exhibition with its advanced PCB splitter solutions, attracting the attention of many industry insiders.

2024-12-17.At this CMM exhibition, Genimax's senior technical consultants brought a complete set of SMT whole-line panel separation technology solutions, targeting different customer needs and different application products, providing visitors with cutting-edge information on the SMT industry, helping everyone solve the confusion in the process of various PCBA panel separations, and demonstrating strong technical innovation capabilities.

2024-11-19.In order to let everyone have a deeper understanding and feel the customs and connotations of Chinese traditional festivals, Zhimao's fully automatic PCBA board splitting machine manufacturer has carried out DIY mooncake making activities every year when the Mid-Autumn Festival comes, so that Zhimao's employees can experience the happy atmosphere of the Mid-Autumn Festival while learning the excellent traditional Chinese culture.

2024-11-19.In order to further care for the health of Guan Zhimao's family, enhance cohesion and continuously improve employees' sense of happiness and belonging, we guide everyone to develop a healthy lifestyle and habits, maintain a positive attitude, and "early detection, early diagnosis, and early treatment" of abnormalities in physical examinations to ensure physical and mental health and stay away from diseases.

2024-11-19.The punching machine drives the die to press down at high speed, instantly cutting off the connection parts of the PCB (such as the residual substrate at the V-Cut or the stamp hole bridge) with a pressure of several tons to tens of tons. After the punching is completed, the die retreats and the separated small boards are removed by the conveyor belt or robot.

2025-04-14.In daily production, although the guillotine-type PCB splitter is easy to use, it will always encounter various problems. Zhimao PCB splitter has sorted out five small points for your reference.

2024-11-19. 2024-11-19.Preparation steps for the operation of the PCB milling cutter board splitter: 1. Check the peripheral environment of the PCB milling cutter board splitter, whether there is water accumulation in the electrical box and filter, and whether each motion axis is movable. 2. Start the machine step by step: Before starting the machine, you must check whether the input power supply voltage of the equipment is missing or too low. After the power is turned on for about 10 minutes, the voltage is stable.

2024-11-19.A complete list of PCB milling cutter splitting machines, what are the types of gong machines?

2024-11-19.