Suitable for cutting large PCB boards:

GAM330: 300*350mm

GAM330L: 450*500mm

GAM330X: 470*650mm

High-speed CCD visual automatic correction system ensures the accuracy of each cut

The machine is equipped with a high-speed CCD visual automatic correction system, which can achieve accurate positioning and cutting of PCB boards. Improve cutting efficiency and ensure the accuracy of each cut, making the board splitting more efficient and stable.

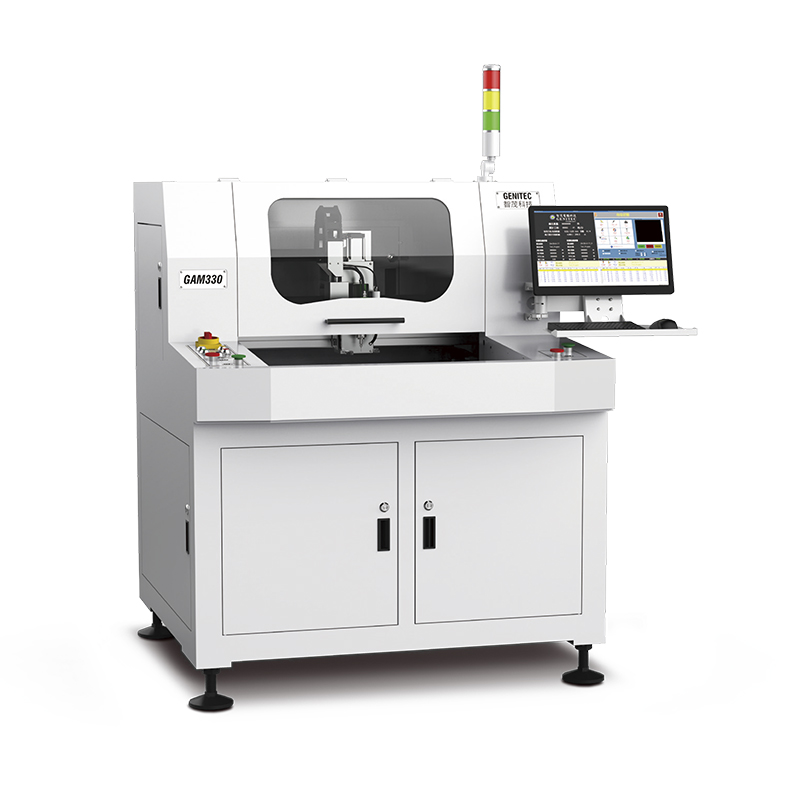

Automatic tool change spindle, saving time and effort

The equipment adopts an automatic tool change spindle, which greatly saves manual tool change time; it not only improves production efficiency, but also eliminates operator errors, making the board splitting higher quality and more efficient.

Precision screw drives the platen in and out, with fast speed and high precision

The GAM330 offline board splitter uses a precision screw to drive the platen in and out, ensuring fast speed and high precision during the cutting process. Whether it is a thin plate or a thick plate, the equipment can easily complete the cutting task and escort your product quality.

Double workbench design, flexible response to various production needs

The equipment is equipped with a double workbench, which can perform board splitting and manual board placement operations at the same time, reducing waiting time and improving efficiency. In addition, the double workbench can be combined into a single board, which can flexibly cope with the cutting needs of super large PCB boards and save costs.

Multiple optional software and hardware functions to meet personalized needs

To meet the personalized needs of different customers, the GAM330 offline board splitter provides multiple software and hardware optional functions. These functions can be customized and configured according to actual needs to better meet production needs.

Use upper or lower vacuum cleaners to ensure that there is no dust after PCB board splitting

Use upper or lower vacuum cleaners to flexibly cope with different production scenarios, ensuring that there is no dust residue on the surface of the PCB board after PCB board splitting, and no dust residue in the working area. It not only improves the cleanliness of the equipment production environment, but also ensures the smooth progress of subsequent processes.

The end mill height can be automatically compensated to ensure the correct cutting depth.

During the panel separation process, the system detects abnormalities such as end mill slippage, broken tools, or improper installation, preventing PCBA damage.

An optional end mill diameter detection function, combined with end mill usage records, makes tool management easier.

The account password can be set to differentiate user permissions for different levels of personnel according to management needs.

A fingerprint recognition module can be added for convenient management.

Equipped with high-speed CCD vision automatic calibration system.

Can simulate cutting paths to assist in program programming, ensuring cutting path accuracy.

Combined with full-board scanning and offline programming functions, it enhances path editing efficiency.

Cutting programs can be edited offline and directly imported into the machine, improving utilization rate.

Simpler, more user-friendly, with automatic recognition of cutting paths.

After full-board PCB scanning, editing allows for quick modifications to cutting paths, improving programming efficiency.

Cutting line colors are selectable, making it easier to identify different color PCBs.

Maintenance time can be set.

Time to clean the dust filter bag.

The system will remind operators to perform maintenance on the equipment regularly.

With over 30 years of independent software development, the PCB depaneling machine uses self-developed software, ensuring stability and reliability, and preventing board damage caused by bugs.

Item | GAM330 | GAM330L | GAM330X |

Valid cutting size | 300*350mm | 450*500mm | 470*650mm |

Cutting function | Linear, circular, and arc interpolation | ||

Processing table | Dual tables | ||

Repeat Precision | ±0.01mm | ||

Cutting Precision | ≦±0.05mm | ||

Maximum Moving Speed | XY Axis:1000mm/s、Z Axis:500mm/s | ||

Maximum Travel Distance | X:800mm, Y:490mm, Z:90mm | X:1090mm, Y:690mm, Z:90mm | X:1090mm, Y:790mm, Z:90mm |

Spindle Speed | MAX.60000rpm Adjustable | ||

Spindle Tool Change Method | Automatic tool changer | ||

Tool Detection | Equipped with automatic broken tool detection | ||

Cutting Speed | 0~100mm/s Adjustable | ||

Operating System | Windows10 | ||

Program Teaching Method | Intuitive teaching by CCD color image imput | ||

Program Backup | USB Interface | ||

Control Method | Precision three-axis control system | ||

XYZ Axis Drive Method | AC servo motor | ||

Applicable Router bit Size | 0.8~3.0mm | ||

Main Power Supply Specification | 2.2KW Single phase | ||

Main Air Supply Requirement | 0.6Mpa ,75L/min | ||

Dimensions | 1220*1150*1458mm | 1500*1497*1453mm | 1510*1650*1453mm |

Weight | 480kg | 600kg | 660KG |

Suitable for processing small multi-connected boards such as mobile phones, car electronics, CCD, etc., and the larger size is suitable for large circuit boards such as digital TVs and servers