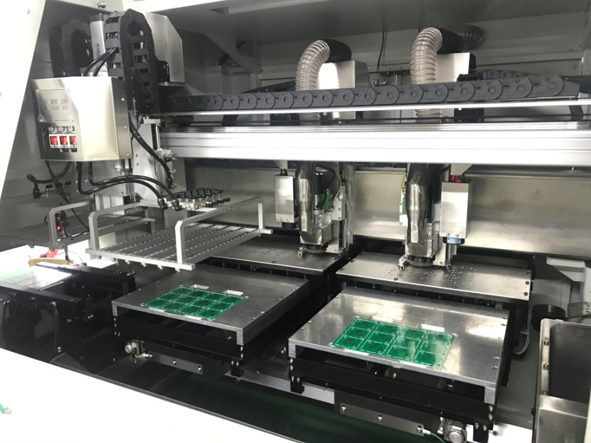

Two ESD anti-static high-precision imported spindles double the production capacity and save costs.

The whole machine adopts a gantry high-rigidity structure to ensure the machine's accuracy and stability

Dual-cutting Z-axis module, two ESD high-speed spindles and left and right plates simultaneously perform plate separation operations, doubling production capacity.

The flying camera machine automatically adjusts the focus height without manual adjustment

Patented floating brush structure, the milling cutter can be used in sections, effectively extending the service life of the milling cutter and brush

The end mill height can be automatically compensated to ensure the correct cutting depth.

During the panel separation process, the system detects abnormalities such as end mill slippage, broken tools, or improper installation, preventing PCBA damage.

An optional end mill diameter detection function, combined with end mill usage records, makes tool management easier.

Equipped with high-speed CCD vision automatic calibration system.

Can simulate cutting paths to assist in program programming, ensuring cutting path accuracy.

Combined with full-board scanning and offline programming functions, it enhances path editing efficiency.

Cutting programs can be edited offline and directly imported into the machine, improving utilization rate.

Simpler, more user-friendly, with automatic recognition of cutting paths.

After full-board PCB scanning, editing allows for quick modifications to cutting paths, improving programming efficiency.

Cutting line colors are selectable, making it easier to identify different color PCBs.

With over 30 years of independent software development, the PCB depaneling machine uses self-developed software, ensuring stability and reliability, and preventing board damage caused by bugs.

Adopt High-Power Dust Collector

Dust Filtration with HEPA Grade

Equipped with Negative Pressure Detection, providing real-time alerts for dust collection status

Equipped with Floating Brushes (Invention Patent No. ZL201721620742.X) to enhance dust collection efficiency

Item | GAM330AD | GAM340AD |

Valid cutting size | 350*300mm | 450*420mm |

Loading/Unloading method | Track delivery | |

Movement direction | Left to right or right to left | |

Cutting precision | Tweening to straight line, L shape ,U shape ,Circle ,Arc | |

Repeat precision | ±0.01mm | |

Cutting precision | ≦±0.05mm | |

Max moving speed | XY:1000mm/sec,Z:500mm/sec | |

Spindle | Two automatic tool change ESD high-speed spindles | |

Spindle speed | MAX80,000rpm | |

Cutting speed | 1-100mm/s Adjustable | |

Operating system | Windows10 | |

Program teaching mode | Intuitive teaching by CCD color image input | |

Control Method | Precision multi-axis control system | |

Size of milling tool | φ0.8-3.0mm | |

Demensions | 2105*1662*1716(mm) | 2210*1554*1745(mm) |