Equipped with automatic tool change mechanism to avoid work-related injuries and misoperation

Equipped with automatic tool breakage detection function

Z-axis equipped with automatic compensation setting to automatically adjust the milling cutter depth

Single workbench occupies a small area and has high applicability.

Equipped with high-speed CCD visual automatic correction system to improve recognition efficiency.

Adopt imported high-speed spindle, with small splitting stress and high precision.

Equipped with high-suction upper dust collector, with good dust collection effect.

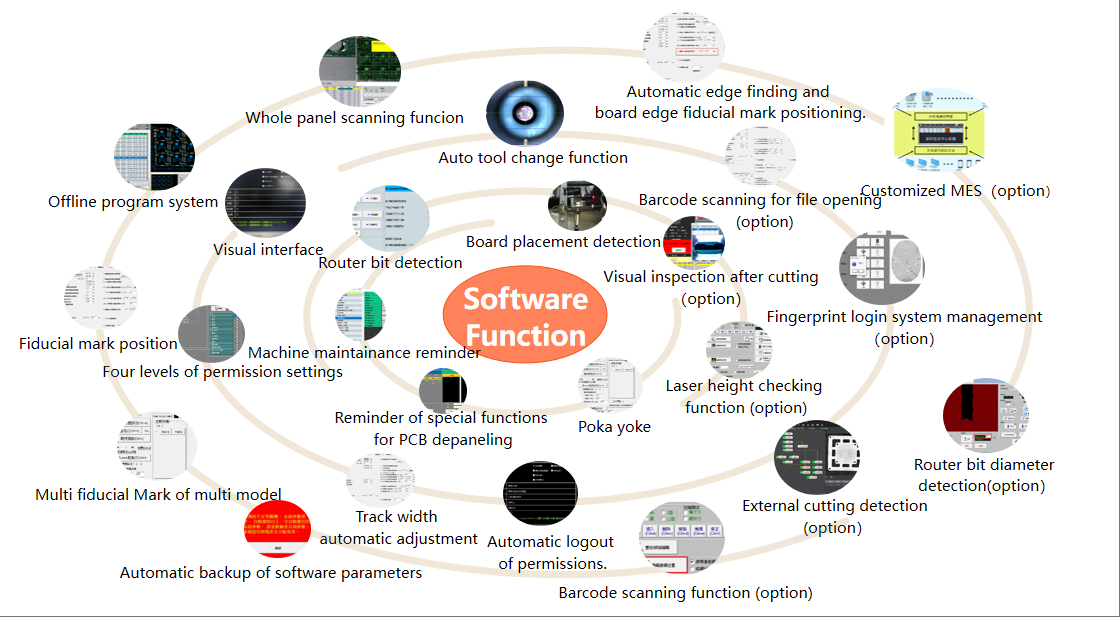

Windows operating system, safe, stable, easy to learn and use.

The panel separation function and parameters for end mills/fixtures are easy to set.

Processing efficiency and end mill usage data are clearly displayed.

The historical message pane makes it easy to query operation records.

It features router bit life management, maintenance alerts, and spindle speed settings management.

The end mill height can be automatically compensated to ensure the correct cutting depth.

During the panel separation process, the system detects abnormalities such as end mill slippage, broken tools, or improper installation, preventing PCBA damage.

An optional end mill diameter detection function, combined with end mill usage records, makes tool management easier.

The account password can be set to differentiate user permissions for different levels of personnel according to management needs.

A fingerprint recognition module can be added for convenient management.

Equipped with high-speed CCD vision automatic calibration system.

Can simulate cutting paths to assist in program programming, ensuring cutting path accuracy.

Combined with full-board scanning and offline programming functions, it enhances path editing efficiency.

Cutting programs can be edited offline and directly imported into the machine, improving utilization rate.

Simpler, more user-friendly, with automatic recognition of cutting paths.

After full-board PCB scanning, editing allows for quick modifications to cutting paths, improving programming efficiency.

Cutting line colors are selectable, making it easier to identify different color PCBs.

Imported high-speed, high-precision spindle.

Low cutting stress, smooth edges, and high precision.

High-precision spindle speed: 80,000 rpm/min

| ITEMS | GAM310A |

| Valid cutting area | 350*300mm |

| Process table | Single tables |

| Cutting function | Tweening to line, L shape, Circle, Arc |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.05mm |

| Max moving trip | X:450mm,Y:480mm,Z:90mm |

| Spindle speed | Max.80000RPM Adjustable |

| Size of milling tool | Ø0.8-3.0mm |

| Cutting speed | 1-100mm/s |

| Operating system | Windows10 |

| Program teaching method | Intuitive teaching by CCD color image input |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Power | Single phase AC220V 50/60HZ |

| Dimensions (W x D x H)mm | 840*1208*1530mm |

| Dust collector | TS300 |

Suitable for PCBA sub-boards of various small multi-connected boards such as mobile phones, digital cameras, GPS, PDA, etc.