Three-section track online, specially designed for SMT production line

No contact, no stress, low dust, fast and flexible, high production capacity

The maximum processing size can reach 350x350mm format, with a compact structure, which can be quickly incorporated into the SMT production line. By loading different product fixtures, the standard three-stage track loading and unloading structure can easily realize the switching of various products;

Safe and reliable, in line with the design of Chinese and EU electrical standards, the processing area is fully enclosed to ensure the safety protection of the processing process;

According to production needs, it can be connected to the factory MES system to achieve full-process production control.

Standard track online, fast access, with outstanding advantages such as non-contact, stress-free, low dust, fast and flexible, and high energy efficiency ratio.

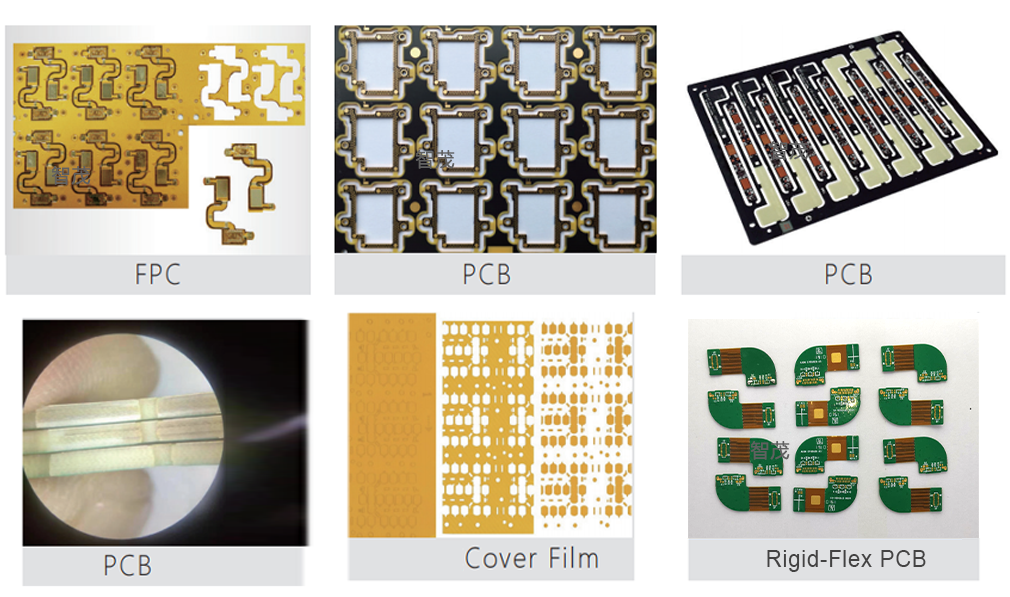

Laser precision cutting has high precision and can meet various board splitting needs such as full cutting, breakpoint cutting, stamp hole cutting, V-CUT cutting, etc. The products are not restricted by graphics and will not deform.

Suitable for the application of high-end precision products, the products after processing are burr-free and smooth and neat.

Equipped with high-speed CCD vision automatic calibration system.

Can simulate cutting paths to assist in program programming, ensuring cutting path accuracy.

Combined with full-board scanning and offline programming functions, it enhances path editing efficiency.

Maintenance time can be set.

Time to clean the dust filter bag.

The system will remind operators to perform maintenance on the equipment regularly.

By adding a laser height measurement module, the height of the PCBA when placed into the fixture can be checked to ensure it is correct, preventing cutting deviation and damage during the depaneling process due to improper placement of the PCBA or small debris inside the fixture.

The barcode camera can dynamically capture and recognize QR codes from any position in real-time applications.

By adding a barcode reader, the barcode on the PCBA can be recorded to the computer, or the MES system can receive server messages to identify the NG board's barcode and perform classification processing.

With over 30 years of independent software development, the PCB depaneling machine uses self-developed software, ensuring stability and reliability, and preventing board damage caused by bugs.

Optional Central Control System: Unified management and real-time monitoring via network IP.

Remote Device Unified Management: Remote monitoring via mobile app.

Item | ZAM340 |

Maximum carrier size | 350mm×350mm |

Platform | Granite platform, linear motor |

X/Y axis resolution | 0.5μm |

Repeatability | ±25μm |

Receive data format | ±2μm |

Laser wavelength | Gerber, HPGL, Sieb & Meier, Excellon, ODB++ |

Nanosecond laser pulse frequency | 355nm/532nm |

Dimension(WxHxD) | 40kHz-300 kHz |

Weight | 940mm x 1,720mm x 1,650mm |

Power Supply | 1500kg |

Ambient Temperature | 3×380V+N+PE, 50Hz, 3.0kW |

Laser | 22℃±2℃(71.6℉±2℉) |

Data processing software | Option |

Driver software | CircuitCAM7 |

Camera target alignment system | DreamCreaTor |

Industrial vacuum system | Standard |

Maximum carrier size | Option |