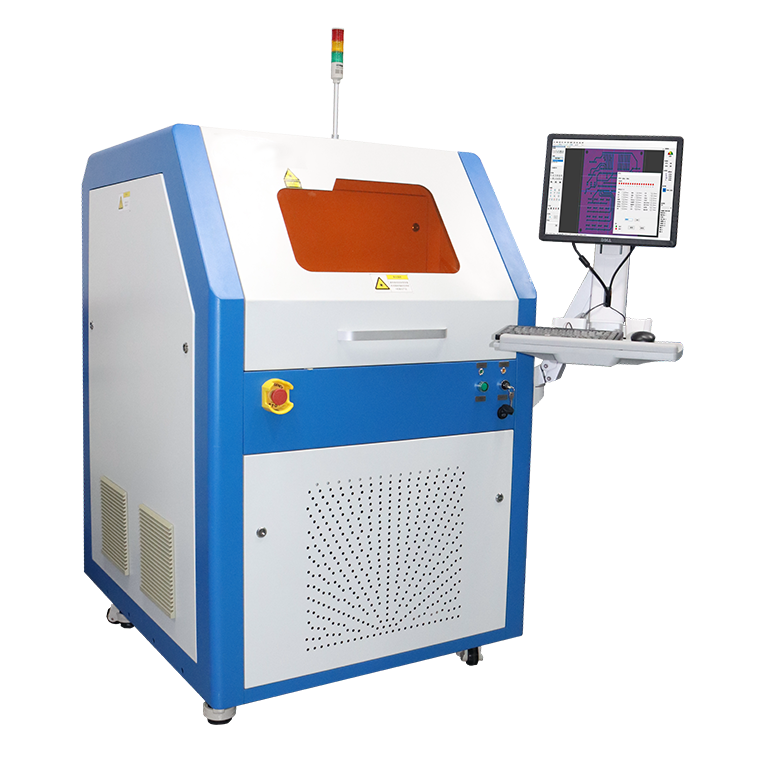

Non-contact board separation

No dust, no stress

Ultra-high precision at micron level

Direct data drive: immediate production, fast product introduction

High degree of automation: equipped with a conveyor, ready to enter the line at any time, high degree of automation

Breaking through mechanical limits: laser replaces molds, avoids distortion, and breaks through mechanical limits

Contactless processing: materials sublimate when exposed to light, no contact is required, and stress damage is eliminated

Precise laser control: Precise laser control, fixed depth and quantity, micron-level extreme structure

project | ZAM310H |

Platform type | Single platform |

range of work | 300*350mm |

repeatability precision | ± 2μ m |

Overall accuracy | ± 25μ m |

X/Y resolution ratio | 1μ m |

Thickness of processable material | ≤ 2.0mm |

platform structure | steel structure |

Motor type | servo motor |

Laser type | nanosecond |

laser power | 15W |

Range of telecentric lenses | 50*50mm f=100mm domestic zoom lens |

CCD structure | paraxonic |

positioning accuracy | 0.01mm |

Camera resolution | One and a half million |

Equipment control software | DreamCreaTor 3 |

Data processing software | Circuit CAM7.5 Standard |

file format | LMD, standard Gerber (RS-274-D), extended Gerber (RS-274-X), DXF, Excellon, Sieb & Meier, HP-GL, Barco DPF, ODB++ |

work environment | 22℃ ± 2℃ |

source | 380VAC/50Hz/2KW |

weight | About 580Kg |

Size (length * width * height) | 930*1270*1600mm |