Precise thermal control, clean processing

Multi-function, safety

High speed, high precision

Easy and fast operation

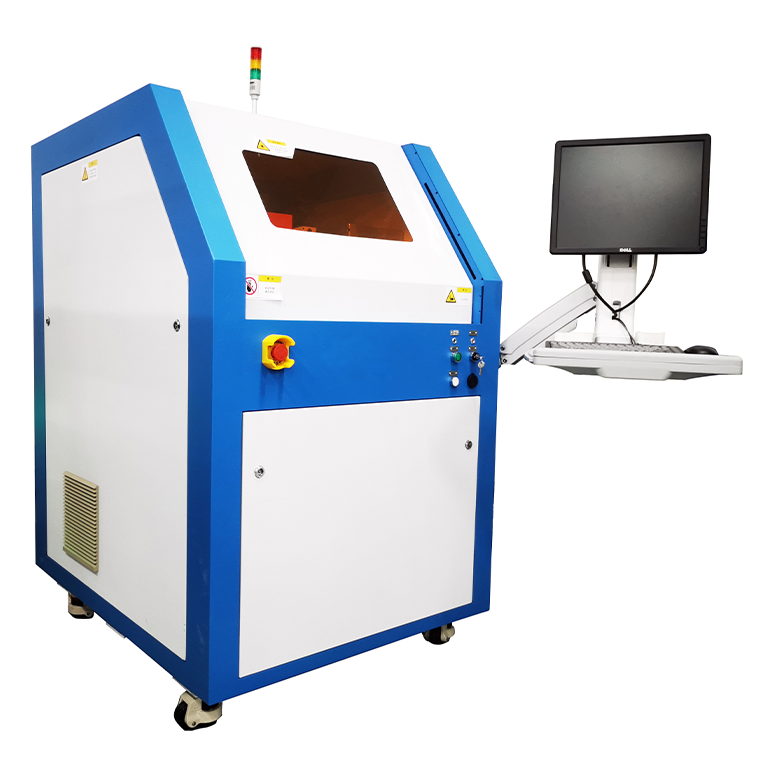

High-precision, high-quality, new standards for small-format equipment. With the rapid development of electronic technology, designers are assembling more and more dense, smaller, and more and more components onto smaller, thinner, and more irregular circuit boards, which brings greater challenges to the subsequent board separation process. To this end, Zhimao provides a more environmentally friendly, fast, precise, and reliable solution to meet the needs of this trend.

Equipment features:

Direct data drive: immediate production, rapid product introduction

High degree of automation: equipped with a feeder, ready to enter the line at any time, high degree of automation

Breaking through mechanical limits: laser replaces molds to avoid distortion and break through mechanical limits

Non-contact processing: the material sublimates when it encounters light, no contact is required, and stress damage is eliminated

Precise laser control: precise laser control, fixed depth and quantity, micron-level extreme structure

Item | ZAM310 |

Max. Working Area | 350mm×350mm |

Working Table | A-Steel Frame, Servo Ballscrew/B-Marble Table,Linear Motor |

Machine Accuracy | ±25μm |

Repeatability | ±2μm |

X/Y Axis Resolution | 1μm |

Receive Data Format | Gerber, HPGL, Sieb & Meier, Excellon, ODB++ |

Laser | Green laser, UV laser, PS laser, NS laser. |

Dimension(WxHxD) | 1050mm x 1,600mm x 1,270mm |

Weight | 600kg |

Power Supply | 3×380V+N+PE, 50Hz, 3.0kW |

Ambient Temperature | 22℃±2℃(71.6℉±2℉) |

Laser | 15W/20W Option |

Data Processing Software | CircuitCAM7 |

Machine Driving Software | DreamCreaTor |

Automatic Loading and Unloading System | Option |

Laser Height Sensor | Option |

Camera Positioning | Option |

Exhaust Unit | Standard |