Simple small PCB splitter, high production efficiency, 1 second cutting

After soldering, the boards connected to multiple pieces often break and damage the circuit or break the electronic parts. This machine uses a knife-moving cutting method to completely reduce stress, prevent cracking of solder joints and breakage of parts, and improve production efficiency and quality.

The upper round knife and the lower flat knife are used. The board is placed on the lower flat knife. Once the switch is pressed, the upper round knife moves horizontally to the set point, and the PCB board is cut and divided. The cutting does not fall off, the incision is flat, and there is no burr.

Completely independently developed, using microcomputer program control, precise fixed point, strong stability. Cut a single board within 0-560MM in length with one knife.

The cutting board cutting speed can be adjusted to high and low, with speeds of 500mm/S and 300mm/S. If the knife speed is fast, the product quality can be improved, without burrs and burrs.

The knife wheel travel: 0-560mm (the knife length can be customized). The upper and lower height of the knife wheel can be fine-tuned: 0-2mm to adapt to various PCB board thicknesses, solving the problem of the depth of the V-CUT groove of the PCB board. The height of the operating table can be adjusted: 0-50mm.

The knife travel can be set according to the length of the board to set the forward stop point, and the stop point is set manually.

The depth range of the rear baffle: unlimited. The maximum board cutting width: unlimited, the maximum board cutting length: 560mm, the maximum board thickness: 0.2-5mm, the maximum thickness between the V grooves: 0.25-2.0mm.

The upper and lower knives are made of imported high-speed steel, which is extremely durable. When the knife is not good, it can be re-grinded.

A conveyor belt can be added to facilitate the automatic delivery of the cut PCB board.

The lifting platform, the platform is raised, which affects the quality of the product, is not easy to damage the product, and can reduce stress.

The limit device can be used for products of different sizes, thereby improving work efficiency.

project | ZM30 |

Knives | Round knife diameter125mm |

Cutting thickness | 0.2-3.2mm |

Blade material | Imported high speed steel |

Die cutting accuracy | ±0.1MM |

Equipment power supply | AC230/110V 50-60HZ,40W |

Equipment weight | 37KG |

size | L650*W340*H430mm |

Cutting stroke | 330mm,460mm,560mm |

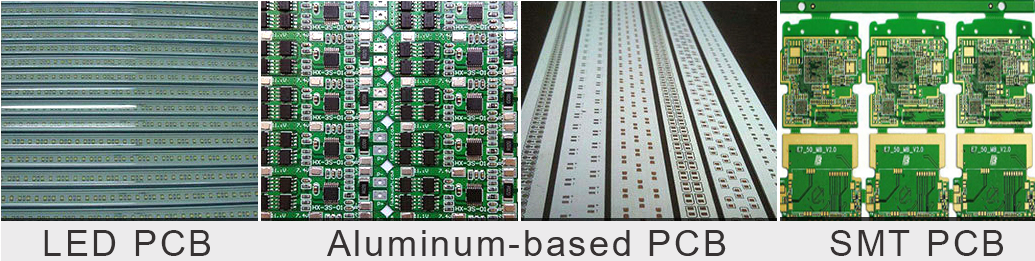

Applicable to all kinds of PCB circuit boards with V grooves, aluminum substrates, LED circuit boards, LED light strips, etc.

Mainly used in electronic industries such as LED, SMT, mobile phones, toys, and various industries using circuit boards.