High efficiency, 6 to 8 panels can be divided into one minute

High efficiency, 6 to 8 panels can be cut in one minute.

The surface of the cut products is flat and the size is uniform.

Low noise and no dust generation, thus reducing pollution to the environment.

Low energy consumption, the main power is compressed air.

Low labor intensity for employees.

The lower die is automatically cut in and out, and it is protected by gratings and safety doors at the same time, which makes the operation very safe for operators.

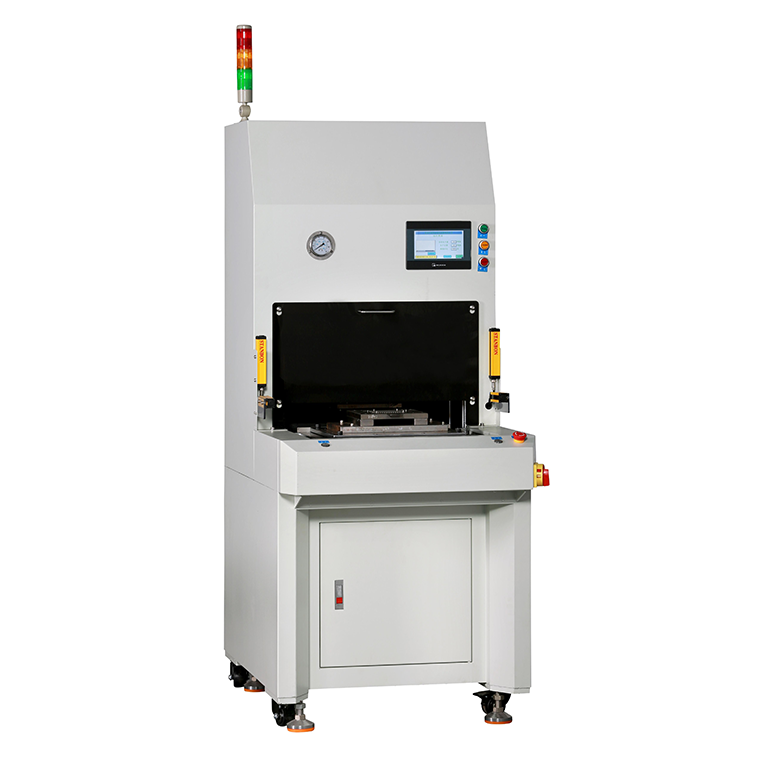

1.Machine Exterior Sepecifications | Machine Name | FPC/FPC Punch Cutting Machine |

Model | ZM10T / ZM15T | |

Outsize | 1070*1070*2079MM | |

Shape | Vertical | |

Weight | 600KG | |

Color | Grayish white | |

2.Machine Supply Requirements | Power Supply | AC220V 200W |

Enviroment Required | Clean and dry environment ,Avoid moisture or high temperature environment | |

Working Pressure/Pipe Dia. | 》0.6MP /6mm | |

Minimum distance of part from cutting position | ≥=0.5mm | |

Max.Cutting Length | 300*350mm / 250*350mm (Can customize larger size) | |

FPC Cutting Position | Don’t allow components to cross above the cutting position | |

Position Hole Required | FPC has4 holes at least and extra one foolproof hole | |

Max.height of the FPC Components | Bottom side the max.height is :20mm Top side the max.height is 35mm | |

3.Machine Software Part | PLC | OMRON PLC |

Paramenters Setting | Can set the punch cut times through touch screen,and the maintenance time of the cutter time etc. | |

Storage Module | Can store 50 sets of programs | |

Operating System | Chinese and English optional | |

Touch Screen | WEINVIEW Touch Screen | |

Fiber Optic Sensor | Daochuan Sensor |

PCB board, FPC flexible board, and hard-soft board cutting cases of stamping board cutting machine