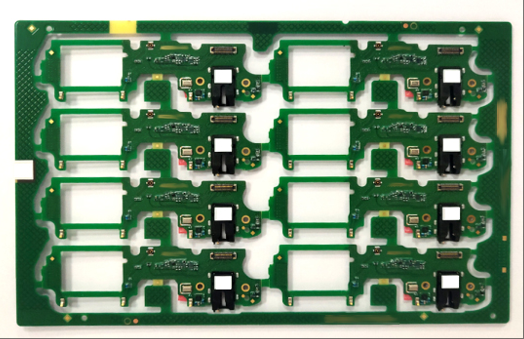

Suitable for cutting high-component PCB boards of various complex shapes, flexible and efficient

Cutting range 300*350mm (double table), can be used with single table 620*350mm

Dual working platform, reducing waiting time for workpiece placement and increasing production capacity

Downward cutting type board separation, suitable for PCB with higher upper components

Provide robot arm IO contact

No table in and out, greatly improving safety

The end mill height can be automatically compensated to ensure the correct cutting depth.

During the panel separation process, the system detects abnormalities such as end mill slippage, broken tools, or improper installation, preventing PCBA damage.

An optional end mill diameter detection function, combined with end mill usage records, makes tool management easier.

Equipped with high-speed CCD vision automatic calibration system.

Can simulate cutting paths to assist in program programming, ensuring cutting path accuracy.

Combined with full-board scanning and offline programming functions, it enhances path editing efficiency.

Cutting programs can be edited offline and directly imported into the machine, improving utilization rate.

Simpler, more user-friendly, with automatic recognition of cutting paths.

After full-board PCB scanning, editing allows for quick modifications to cutting paths, improving programming efficiency.

Cutting line colors are selectable, making it easier to identify different color PCBs.

Imported high-speed, high-precision spindle.

Low cutting stress, smooth edges, and high precision.

High-precision spindle speed: 80,000 rpm/min

The patented floating brush reduces stress during cutting

Allowing the milling cutter to be used in multiple stages and extending its lifespan

Maintenance time can be set.

Time to clean the dust filter bag.

The system will remind operators to perform maintenance on the equipment regularly.

| ITEM | GAM386 |

| Cutting Area | 300*350mm / 620*350mm(Combine for one table) |

| Cutting Function | Linear, L-shape, U- shape, Circle, Arc |

| Repeat Precision | ±0.01mm |

| Cutting Precision | ±0.05mm |

| Spindle | Max.80000rpm, ESD spindle with auto-tool change |

| Spindle Tool-change Method | Air valve auto-tool change |

| Milling Tool Detection | With auto-tool change detection function |

| Cutting Speed | 1-1000mm/s Adjustable |

| Milling Tool Holder Qty. | 6 units |

| Operate System | Windows10 |

| Size of Milling Bit | Ø0.8-3.0mm |

| Programme Teaching Method | Intuitive Teaching by CCD Color Image Input |

| Power Requirement | AC220V 50/60HZ Single-phase |

| Machine Dimensions | W:1151mm D:912mm H:1462mm |

| Machine Weight | 340KG |

| Standard Dust Collector | TS200 |