Intelligent detection of area, position, foreign matter, presence of holes, tension

Steel mesh is highly versatile, has traceability, and reports are automatically generated

Automatically detect area, position, foreign matter, holes, tension;

High detection accuracy and large detection range;

Import GERBER data, modular data structure, and check the results immediately within 2-3 minutes;

By measuring the size and position of the steel mesh opening, setting the error range, and comparing with the reference value to see if it is qualified;

Simple and fast operation

Detection items:

Detection of hole defects such as hole deviation, hole accuracy, shape, multiple holes, few holes, area error, edge burrs, etc.

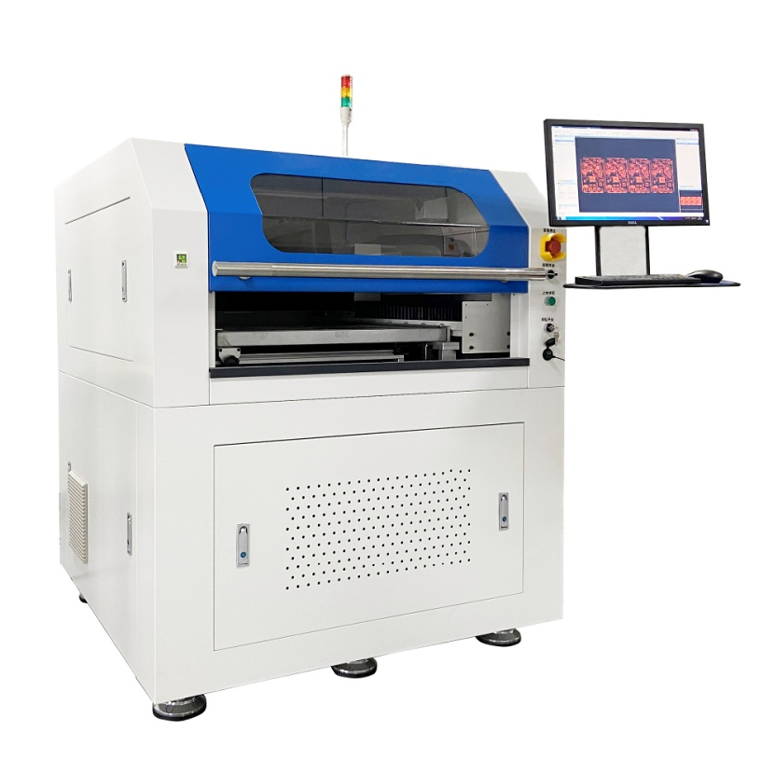

Technical Parameters | ZAM500 Fully Automatic Vision Steel Mesh Inspection Machine |

Measurement items | Opening area, position, offset, size, foreign matter, burrs, blocked holes, few holes, many holes, tension |

measure time | 3.5min (130mm × 100mm standard, data: 25122 holes) |

Opening area measurement accuracy | Gage R&R ﹤5.0% (actual measurement is GR&R ﹤1-2% or less) |

Opening position measurement accuracy | ±10μm |

Transmission mechanism accuracy | Repeatability ±4μm Servo system (resolution: 0.5μm) |

Tension detection | ±0.1N.cm, tension range 0-50N.cm |

camera | 5 million/10 million (default)/12 million/20 million |

Lenses | Bi-telecentric lens |

illumination | Special white LED light source (long strip light source) |

Resolution | Default 6.6μm, customizable |

FOV | 25mm × 18mm (optional) |

Motor | Linear Motor |

platform | Marble platform |

Scan range | 550mm*550mm |