The working principle of Zhimao's stamping PCB depaneling machine is based on *die stamping technology*. Whether it uses servo or electric cylinder, the original principle of the stamping depaneling machine is the same. The core steps are as follows:

1. Custom mold

Customize high-precision molds according to the PCB layout and depaneling path (such as V-Cut or stamp hole connection). The shape of the mold's blade is perfectly matched to the depaneling path to ensure accurate cutting.

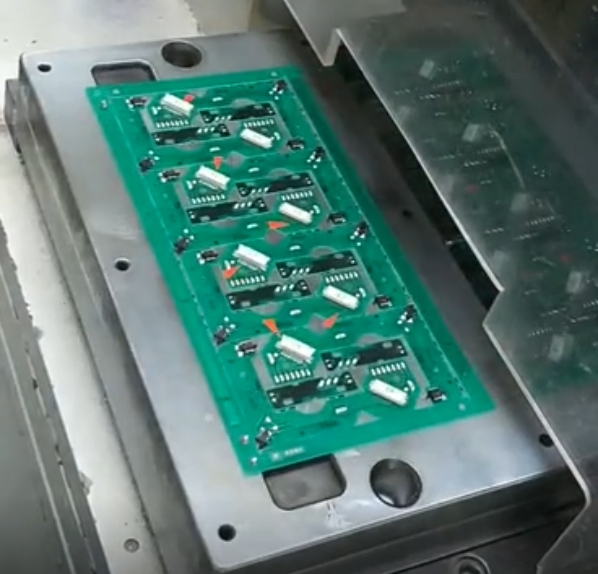

2. Positioning and fixing

The PCB panel is fixed on the stamping platform by mechanical clamps or vacuum adsorption, and the position is calibrated by optical positioning (Mark point) or mechanical positioning holes to ensure that the mold is aligned with the cutting path.

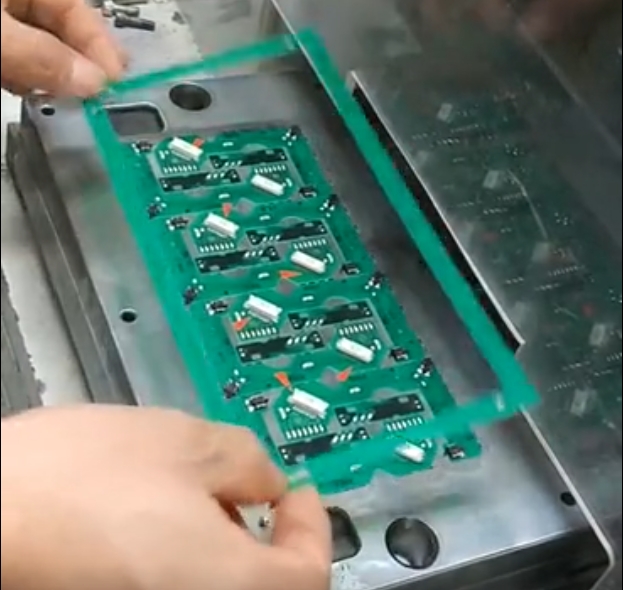

3. Stamping separation

The punching machine drives the mold to press down at high speed, and instantly cuts off the connection parts of the PCB (such as the residual substrate at the V-Cut or the stamp hole bridge) with a pressure of several tons to tens of tons. After the punching is completed, the mold retreats and the separated small board is removed by the conveyor belt or robot.

4. Features of stamping depaneling

-High efficiency: A single stamping can complete the separation of the entire board, which is suitable for mass production.

-High precision: The mold precision is ±0.05mm, the incision is neat, and there is no burr.

-Limitations: The mold cost is high, and it is only suitable for the depaneling path of a fixed single PCB board.

-High stress: Excessive stress can cause damage to solder joints and devices, causing solder ball cracking, circuit warping, device cracking, capacitor failure, etc. (It is necessary to test based on the actual PCB to see whether stamping depaneling can be used)

Through the above analysis of the advantages and disadvantages of the stamping depaneling machine, I believe you have a clearer understanding of the stamping depaneling machine.

If you still don’t know how to choose a suitable stamping depaneling machine, you can contact us and give you a free plan and recommend suitable depaneling machine equipment